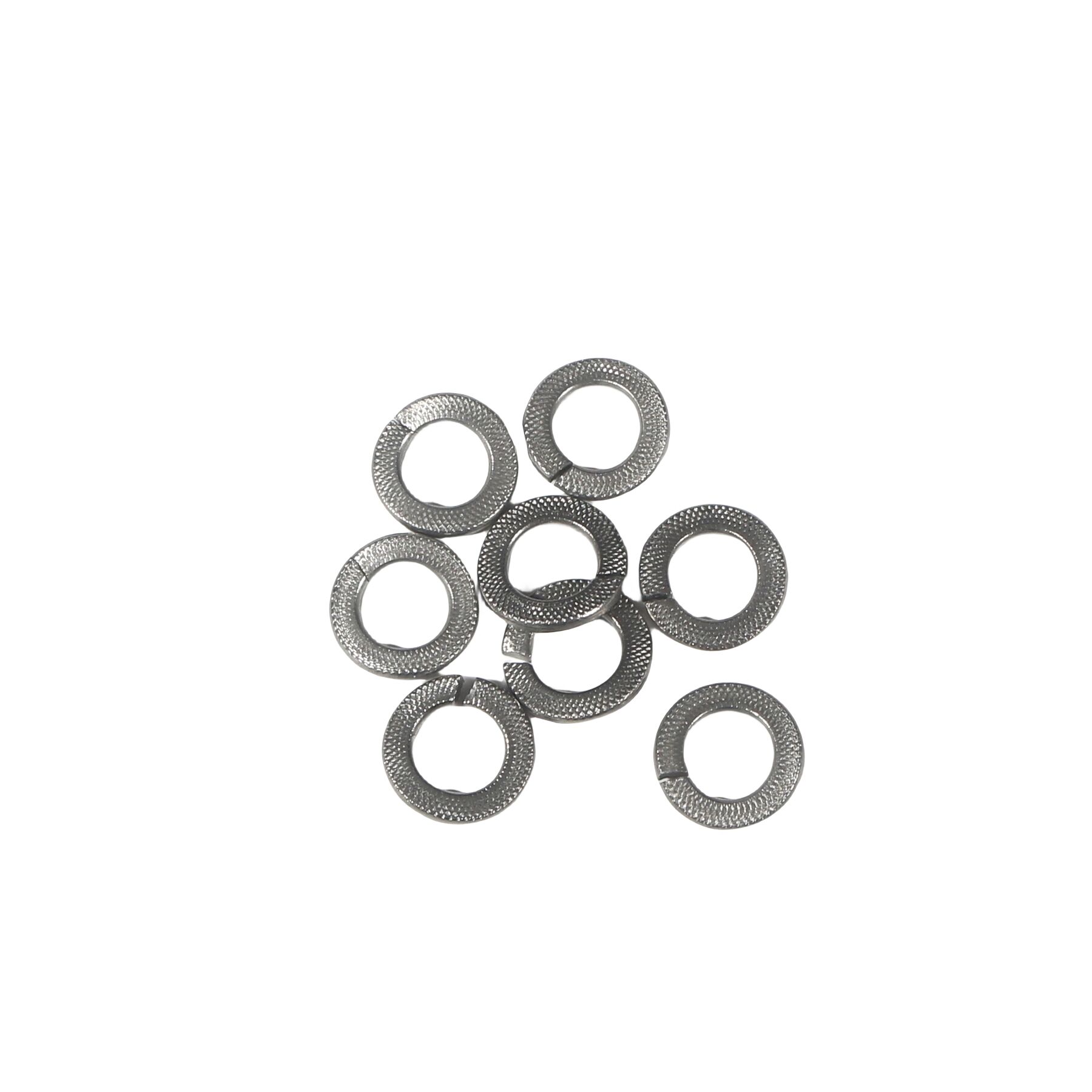

So what are Belleville washers? Belleville washers are essentially small springs shaped like little hats. They are frequently utilized as shims to distribute weight between bolts and nuts in a wide array of machines. Cumulatively stacked belleville washers work even better to distribute weight accordingly. This guide will discuss the benefits of using belleville washer for performance, weight distribution, and proper installation for your best results.

They are often constructed from durable materials such as steel or aluminum. As a result, they can be very effective for use in environments with lots of shaking or movement. As an example, belleville washers help keep parts tight and secure when a machine vibrates during operation. They can also help to prevent bolts from vibrating loose over time, which is necessary for maintaining the safety and performance of machines. Belleville washers can be combined in series, meaning that multiple washers are stacked on each other and can distribute the weight they are required to support. But you must ensure you set them up correctly for maximum performance. Belleville washers in series are actually capable of withstanding heavy weights and provide amazing stability when installed in the correct manner, which is crucial for the safe performance of machines.

We’ll go over some of the key ways in which Belleville washers in series can enhance performance. They can first help to distribute the weight more evenly across the bolt and the nut. This equal distribution allows for reduced stress on the bolt, which further prevents it from snapping. Second, the bent belleville washers can help mitigate shock and vibration to some degree when stacked in series. This provides a natural degree of give when the machine is running, allowing some of the shock that is generated during a run to be absorbed by the belleville washers, as opposed to damaging the machine itself. Lastly, this can be accomplished over time by using belleville washers in series, which can help maintain the necessary tension in the bolt. If the tension begins to relax, the belleville washers will keep the tension sufficient, so the machine would continue working.

Use the correct amount of washers: Depending on the size and weight of your machine, you will need a certain amount of belleville washers. Be sure to always reference the manufacturer's instructions or consult an expert to ensure proper use for your individual application.

Verify even distribution of compression: After you install the belleville washers, it is crucial to ensure that they are compressed evenly. When not compressed evenly, this can cause problems such as the jaw of the bolts breaking, the machine failing altogether, etc.

Safety and performance hinge on proper installation of belleville washers in series. Incorrect positioning of the washers can compromise performance and is likely to result in damaged or completely failed machines. To prevent these problems, always carefully read and adhere to the manufacturer's recommendations when installing belleville washers in series. If you are ill at ease with all the installation steps, it is advisable to contact a specialist before you get started. Theich guidance can help make sure your installation is safe and effective.

Installation and maintenance issues of Belleville washers in series This is, in fact, one of the common challenges. Imbalanced belleville washers cause problems with a machine's performance. This can be avoided by always checking for even compression and adjusting washers if necessary. It's also difficult to decide the number of washers that you need to use. If not enough are used, the machine will become overloaded and ultimately crash, yet for some reason people are not shy of adding more. An expert can help you determine the right number of washers for your application. Finally, the bolt should be re-tensioned at regular intervals. Owing to prolonged use, the washers can begin to lose tension, which can cause performance-related issues with the machine.

Tongxiang WANGU Standard Parts Co., Ltd. is an experienced factory that specializes in spring washers and has more than 15 years of manufacturing experience. We are a leading company in China's spring washer industry. We provide better experiences in procurement of raw materials as well as manufacturing, as well as back-end testing and after-sales service. We can belleville washers in series because we have a vast inventory.

WANGU The company has received the ISO9001:belleville washers in series certification. With advanced production equipment with a strict quality-control mechanism, high-quality scientific research staff and experienced technical staff our products enjoy unbeatable competitive advantages in terms of process quality and costs composition, prices for sales and other aspects.

Our production staff of 30 are professionals and our three test teams run daily tests to ensure the quality of products Additionally under the guidance of ISO9001:2000 our company has belleville washers in series particularly in the after-sales service Beginning with the general manager we endeavor to respond swiftly and efficiently deal with the situation ensuring that buyers don't face unneeded concerns

Tongxiang WANGU company is a reputable producer of spring washers as well as flat washers.The company is primarily involved in the production of spring washers. The main standards include DIN/belleville washers in series/ASME/JIS/UNI/ISO/BS/GB, etc. with specifications that include M1.6-M64 and non-standard series. We have passed ISO9001:2000 Certificate. Our products are highly favored by customers throughout the Americas, Europe, Southeast Asia and many other regions.