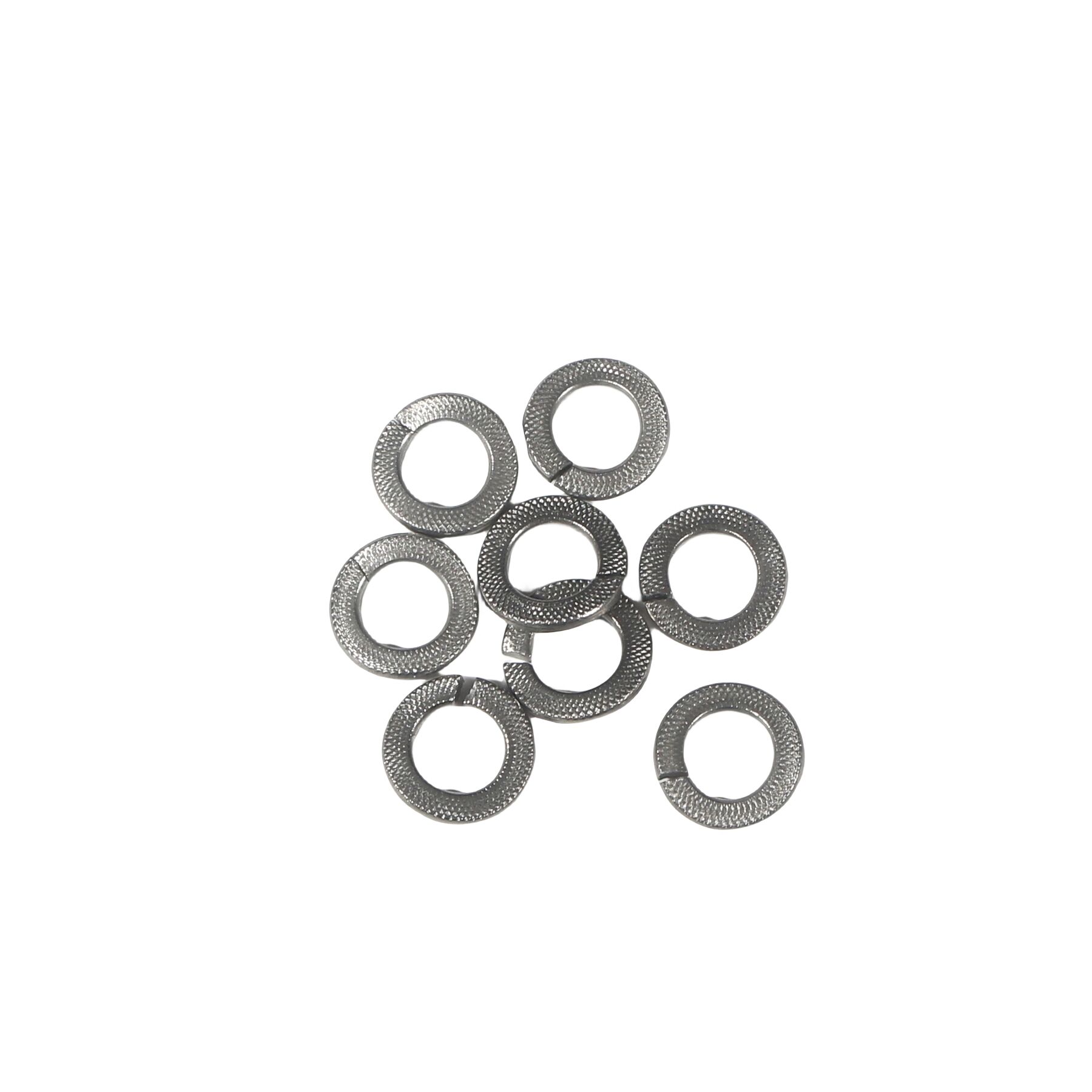

Spring washers DIN 128 are small but at the same time a very important part – they helps to fix bolts and nuts. They may be tiny, but they serve a mighty function in keeping everything where it should be. Time to find out more about these special washers and how they work!

When you’re in need of tightness, DIN 128 spring washers work wonders. The washers are intended to offer extra grip between the bolt and the nut to add stability and prevent the nut from slipping loose. This is particularly relevant in machinery and equipment subject to vibration. In the absence of these washers, bolts and nuts would eventually work themselves loose and cause accidents and damage.

The appropriate DIN 128 spring washer size and material are crucial for its quality. The washer should be of the same size as the bolt and nut. As to the material, you can get stainless steel washers which are durable and will resist corrosion. Just make sure the washers are suitable for the specific purpose they’ll be used for.

Vibration and movement are typical in a machinery or equipment. It can stress bolts and nuts and they may slowly start to become loose. DIN 128 spring washer assist in avoiding this as they keep the bolt and nut under constant tension, preventing them from becoming loose. This not only secures the device, but it also extends the life of the equipment.

When large, heavy-duty assemblies, such as construction or manufacturing, require spring washers, the benefits derived from using DIN 128 spring washers are many. These washers are highly resistant to pressure and tension due to tension and pressure; they are excellent for firm bolting with high pressure, such as joints of pump and housing. With their high strength and reliability, they are also one of the most popular industrial fasteners.

The correct fitting and maintenance of DIN 128 spring washers is a matter of real importance. It's important to ensure the washers are properly positioned between the bolt and nut with the rounded side outwards during installation. With proper care, such as checking for wear and tear, replacing worn-out washers and so on, you can ensure that everything is running exactly as it should be, and you can avoid disasters in the future.

din 128 spring washer 30 production workers are professionals and our three test teams conduct regular tests to ensure the quality of our products. We have also updated our systems in accordance with ISO9001:2000. This is especially the case for the after-sales service. Starting from the General Manager, we try to be prompt and proactive handle the situation, so that buyers don't face no unnecessary worries.

WANGU company has received the ISO9001:2000 din 128 spring washer. Our products are top of the line in the quality as well as cost. We have a highly-qualified research team and a professional technical team.

Tongxiang din 128 spring washer is a manufacturer of flat washers, spring washers and other products.Spring washers are the main product of the company. The main standards include DIN/ANSI/ASME/JIS/UNI/ISO/BS/GB, etc. We offer a variety of specifications, such as M1.6-M64 as well as non-standard series. We are ISO9001:2000 Certified. Our products are extremely favored by customers throughout the Americas, Europe, Southeast Asia, and other regions

Tongxiang WANGU Standard Parts Co., Ltd. is a professional factory specializing in spring washers, with more than 15 years of production experience. We are an industry leader in the Chinese spring washer industry. We offer superior experience in din 128 spring washer and manufacturing, as well as back-end testing, as well as after-sales support. We have a large stock and can ship anytime time. By making use of various management methods which reduce the product costs, which is a biggest advantage in terms cost.