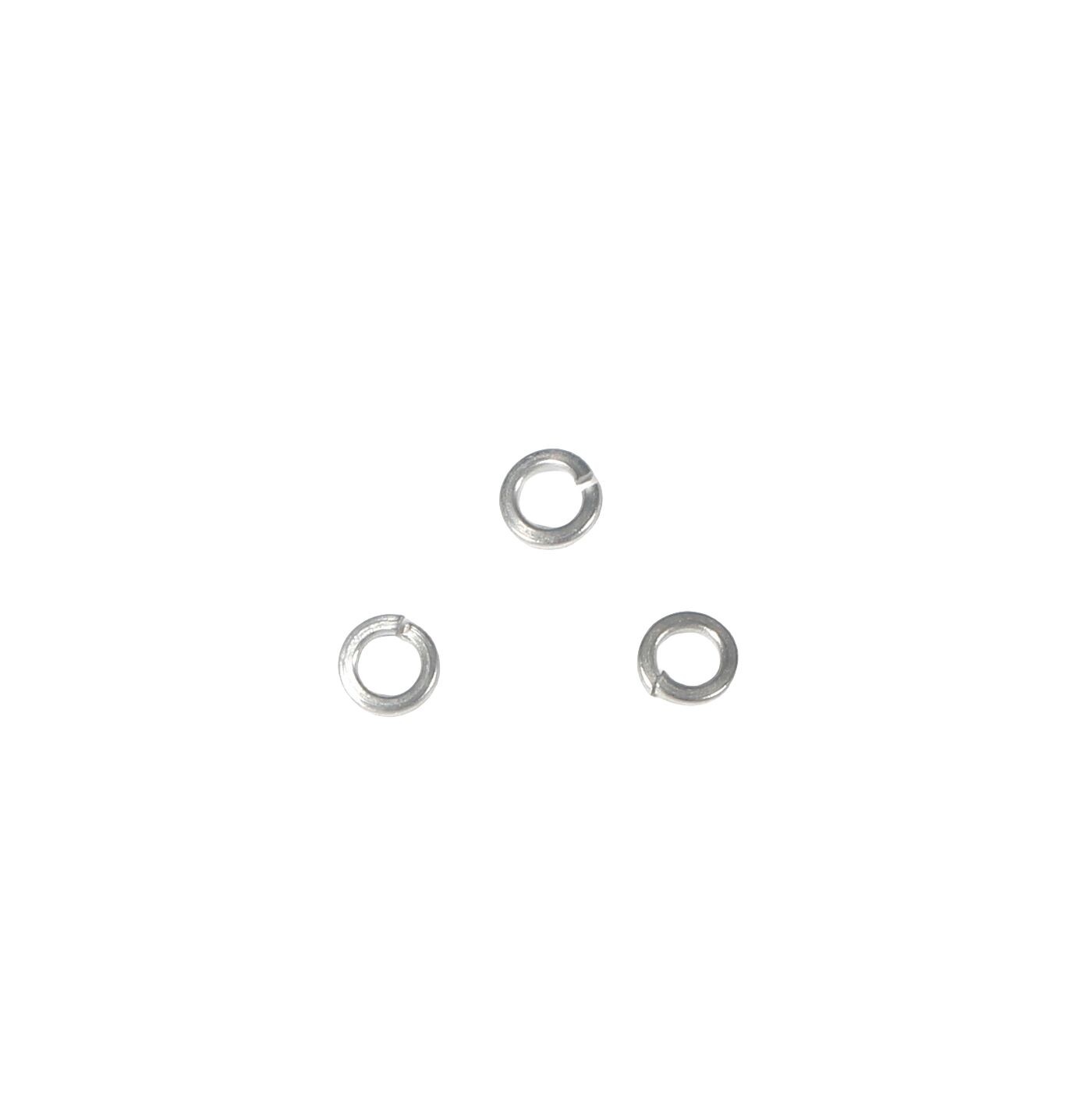

1/4 spring washers are crucial components that serve to maintain the integrity of serialized connections. Fasteners that are used to separate nuts and bolts of various materials, commonly steel, copper or plastic. Regardless of what they’re made of, they all do share one feature in common: they can compress and assist with keeping the connections snug. We also introduce you to why 1/4 spring washers help maintain secure connections, how to select the best option for your business, how to install them properly, the most common issues that can arise with them, and how a 1/4 spring washer is a smart option for fastening products together.

1/4 spring washers are not less significant in securing the connections and preventing machines from shaking apart. These washers, which get pressed together to keep the connection tight. In other words, the parts won't come loose in use. Without a 1/4 spring washer, the shaking or vibrations caused by the machine could loosen the bolts. If this happens, it can destroy the machine and create situations that will kill some people. That is the reason you require for 1/4 spring washers in various circumstances, particularly where security is concerned.

And of course, selecting the right 1/4 spring washer is dependent on understanding exactly what your connection requires. You need to consider things like the size of the bolt you are using, how tight you need to make it, and what materials the connection is going to be around. And if you choose a spring washer that is too small, it may not secure the connection tightly enough, which may later cause problems. If you use one which is too small, for instance, it will not easily fit on the bolt or not function properly, leading to issues as well. Taking time to understand what you need and selecting the right washer for the job is critical.

1/4 spring washer installation is generally a straightforward process, but if you get it wrong, it may not hold the connection tight enough and this could cause issues down the line. First and foremost, ensure that the washer is sized correctly for the bolt being used. This is important because the proper fit will allow for a good connection. Next, you slide the washer between the bolt head and nut, or part being held. Make sure the washer is centered and flat, with no bends or wrinkles. Quite important from a safety/function point of view, a properly installed 1/4 spring washer will keep that connection tight.

Top 4 Problems With 1/4 Spring Washers (Over-Compression Issues) When this happens, they won't be able to keep the connection tight anymore, which is not good. If you want to avoid this issue, you absolutely need to be monitoring the connection occasionally. And, if the washer appears crushed or otherwise damaged, you also need to change it immediately. Another thing that can happen is that the washers move out of place or drop out when you are assembling things. Loose, unsafe connections can occur as a result of this. To prevent this from happening, place the washer correctly before you tighten the bolt so everything remains in its proper place.

1/4 spring lock washers are a well performing and inexpensive solution for many fastening applications. They are created to endure tension over time and will thus save you time and money. This is because you’ll not have to adjust them regularly, nor will have to change them constantly Also, 1/4 spring washers are simple to use and install, making them an ideal option for DIY projects, even if you lack specialized tools or knowledge. That versatility contributes their usefulness to both professional and DIY users alike.

Tongxiang WANGU company is a reputable manufacturer of spring washers and flat washers.The company is primarily involved in the production of spring washers. The main standards include DIN/ANSI/1 4 spring washer/JIS/UNI/ISO/BS/GB, etc. We offer a broad range of specifications, such as M1.6-M64 as well as non-standard series. We are ISO9001:2000 Certified. Our products are adored by customers in the Americas, Europe, Southeast Asia, and other regions

1 4 spring washer is a leading factory, specializing in spring washers with over 15 years of manufacturing experience. It is the leader in the Chinese spring washer industry. We offer buyers greater understanding of raw material procurement, production and manufacturing, backend tests, as well as after-sales service. We are able to ship quickly because we have a vast inventory.

WANGU company has been awarded ISO9001:2000 certification. Our products are 1 4 spring washer superior in both quality and price. We have an experienced research team and a professional technical team.

Our 30 production employees are skilled and our 3 testing teams run daily tests to ensure the 1 4 spring washer of our products Additionally under the guidance of ISO9001:2000 we've changed our systems particularly in our after-sales support We strive to be proactive and react quickly starting with the general manager This helps buyers not be overly worried