Have you ever heard about spring washers? If you’re not familiar with those, I can explain. Spring washers from WAN GU are small metal bits that are very important in maintaining tightness. It is often used with bolts or nuts, to prevent losing them over time. This is very useful because loose bolts or nuts can create trouble in either machines or structures.

One of the most well known varieties of spring washers you’ll come across is the split lock washer. Useful for situations where you need to take things apart a lot. This kind of washer can handle high temperature, which makes it ideal for machines that warm up while they work. Additionally, split lock washers are not corroded and rusty, so they will remain for a longer duration, even under difficult conditions.

This is followed by the wave spring washer. Where space and weight are important issues, this is a suitable washer. A wave washer, for example, can conserve on space where you are operating with a smaller machine or device. It is even flexible since it can be inserted in various manners — it can enter axial (up and down) or radial (side to side) positions. But you should be aware that wave washers are not likely the optimal choice for extremely high-stress applications due to their construction.

Finally, there is the belleville spring washer. This type of spring washer m8 is ideal when you need a heavy-duty spring capable of bending a lot. The durability and wear resistance of Belleville washers make them ideal for applications that require long-term usability. But note that some of them may not be so appropriate for low-pressure work.

Choosing the right spring washer for your application involves several factors. Consider first what you need the washer to do. Think about what the stuff is being utilized for, how much weight does the washer require to hold, and what sort of temperatures will it be. So, there are many factors that contribute to how well the WAN GU spring washer will function.

You also have to consider the spring rate. The spring rate is the amount of force it takes to deflect the washer a specific distance. It’s crucial to tune this spring rate to the weight it will support. If the spring rate is incorrect, you may end up with a product that doesn't work as you were hoping for your application.

ConclusionChoosing the right type of spring washer is one of the most crucial aspects of any engineer and designer’s project. WAN GU has a wide selection of spring washers and other fasteners. We can even manufacture custom-made fasteners specifically tailored to meet your requirements. Our specialist team are always available to offer help in selecting the right spring lock washer for your application and staff members are always available to guide you from start to finish.

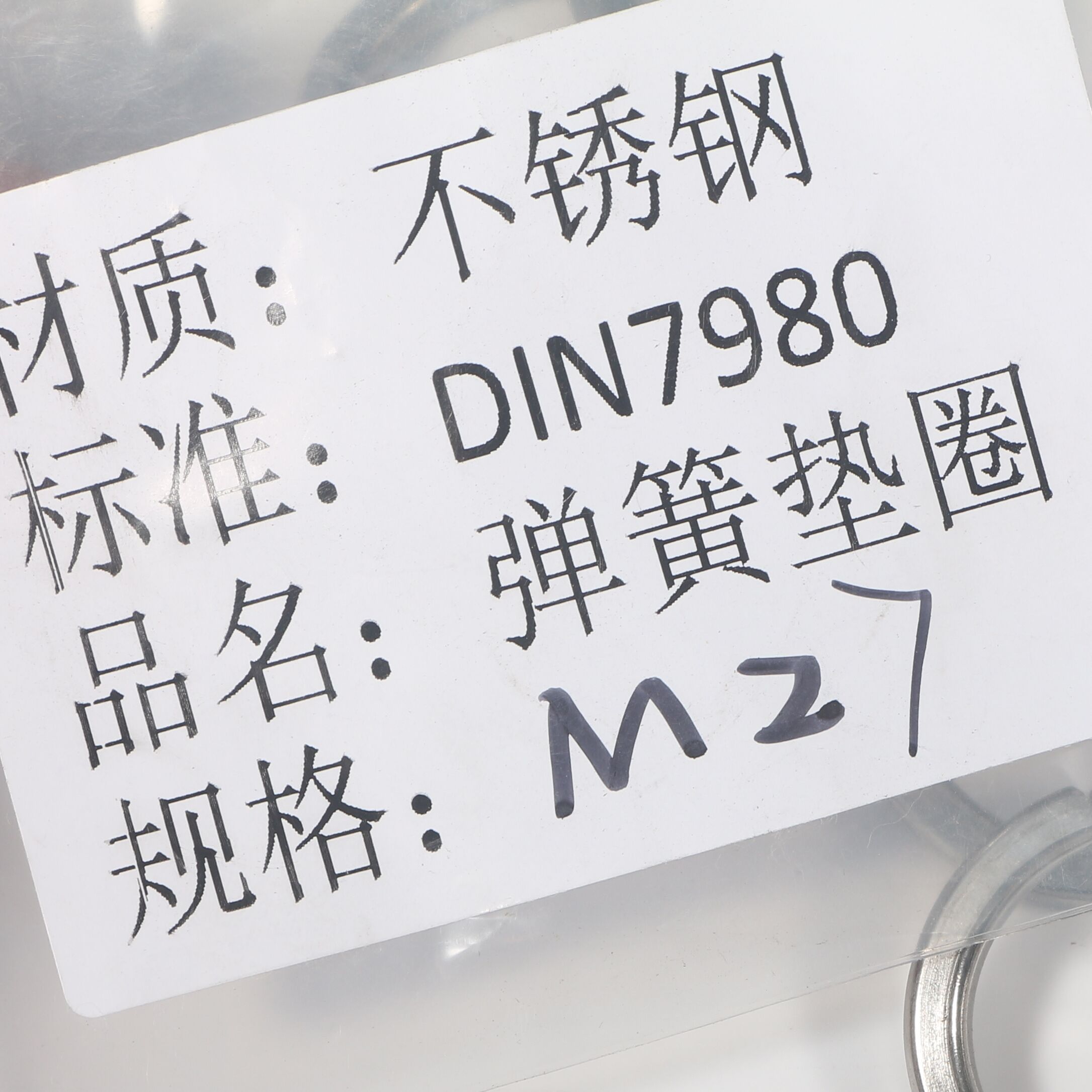

Tongxiang WANGU company is a Spring washer types producer of spring washers as well as flat washers.Spring washers are a major product offered by this company. The main standards include DIN/ANSI/ASME/JIS/UNI/ISO/BS/GB, etc. With the specifications of M1.6-M64 and non-standard series. We have passed ISO9001:2000 Certificate. Our products are highly favored by customers throughout the Americas, Europe, Southeast Asia as well as other regions.

WANGU company has passed Spring washer types:2000 Certificate. Our products stand out in regards to quality and price. We have a high-quality research team and an experienced technical team.

Our 30 production employees are skilled and our 3 testing teams run daily tests to ensure the Spring washer types of our products Additionally under the guidance of ISO9001:2000 we've changed our systems particularly in our after-sales support We strive to be proactive and react quickly starting with the general manager This helps buyers not be overly worried

Tongxiang WANGU Standard Parts Co., Ltd. is an experienced factory that specializes in spring washers that has over 15 years of production experience. It is a leading company in the Spring washer types industry. We give buyers more efficient experience in purchasing raw materials, production and manufacturing, backend testing and after-sales support. We can deliver immediately since we have an extensive stock.