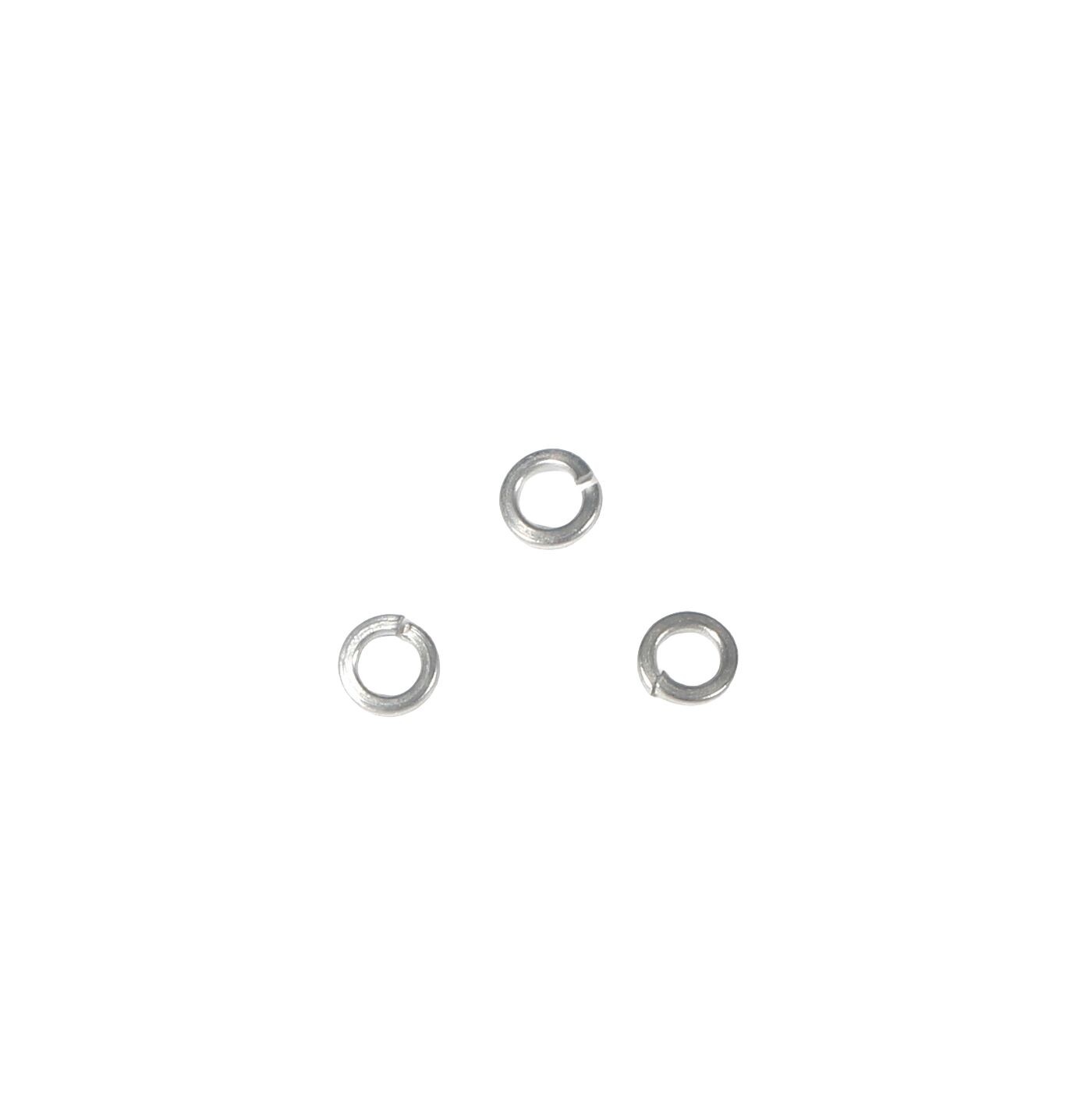

So have you ever wondered how do machines work? Machines use special tools to transport pulley and where this conical washer spring is used. This machine involves a tiny but highly important part known as washer conical spring. So it is made of special metal that is tougher and made to compact (to squeeze and become smaller) then to go back to its original state after pressure on it gets released.

The WAN GU conical spring washer works to reduce shock and vibration, which is the main advantage of using it in the machines. Shock and vibration are actions that an injury can do to your machine, and sometimes, even bring it to a standstill. All parts of a machine can vibrate a lot when the machine is working, and over time these vibrations can damage or break components. The shock and vibrations are cushioned by clearly a washer conical spring. This safety function is super important because it prevents the machine from getting damaged and it works better and longer.

The WAN GU m12 washers conical spring does not protect machines from damage only; It can also increase the performance of machines. Suppose a machine has two parts that must remain snug against one another to function correctly. This spring keeps these two parts tightly enough that they do not come loose. When the parts begin to loosen, they can cause bigger issues that can result in parts cracking or the machine failing altogether.

The spring may also reduce wear and tear on machines. Wear and tear is damage that occurs over time as parts rub against one another or are subjected to too much pressure. The washer conical spring absorbs shock and vibration, reducing stress on the machine parts. Retaining the wear and tear means the machine can continue working properly and it lasts longer before it requires repairs.

So the construction of WAN GU m12 galvanised washers spring enables it to release energy caused by heavy loads or high pressure. This allows the spring to provide the necessary support and protection, even when a machine is under a great deal of stress or weight.

It is very important that you are able to select the correct m12 brass washer conical spring according to the exact job it does, as this will keep your machine for a long time and will have a smooth operation as well.

There are some important factors to consider when choosing the best metal washer conical spring. You should also have to consider the weight of that machine and the environment that the spring will be affected.

Tongxiang WANGU company is a Washer conical spring producer of spring washers as well as flat washers.Spring washers are a major product offered by this company. The main standards include DIN/ANSI/ASME/JIS/UNI/ISO/BS/GB, etc. With the specifications of M1.6-M64 and non-standard series. We have passed ISO9001:2000 Certificate. Our products are highly favored by customers throughout the Americas, Europe, Southeast Asia as well as other regions.

Washer conical spring 30 production workers are professionals and our three test teams conduct regular tests to ensure the quality of our products. We have also updated our systems in accordance with ISO9001:2000. This is especially the case for the after-sales service. Starting from the General Manager, we try to be prompt and proactive handle the situation, so that buyers don't face no unnecessary worries.

WANGU The company has received the ISO9001:Washer conical spring certification. With advanced production equipment with a strict quality-control mechanism, high-quality scientific research staff and experienced technical staff our products enjoy unbeatable competitive advantages in terms of process quality and costs composition, prices for sales and other aspects.

Tongxiang WANGU Standard Parts Co., Ltd. is an experienced factory that specializes in spring washers and has more than 15 years of manufacturing experience. We are a leading company in China's spring washer industry. We provide better experiences in procurement of raw materials as well as manufacturing, as well as back-end testing and after-sales service. We can Washer conical spring because we have a vast inventory.