Have you ever wondered why machines function without falling into pieces? That's where metric spring washers come to rescue! These small, yet powerful features are integral to keeping industrial equipment running smoothly, supplying both strength and versatility where it’s needed the most.

Metric wave washers look like run-of-the-mill, extremely-small elements but are in fact critical to sustaining the position between several machine components. Similar to a sidekick to a superhero, metric wave washers are supporting the bolts and nuts in an assembly and guarding them against losing or falling out during operation. This helps it to keep it running smoothly and avoids accidents from occurring.

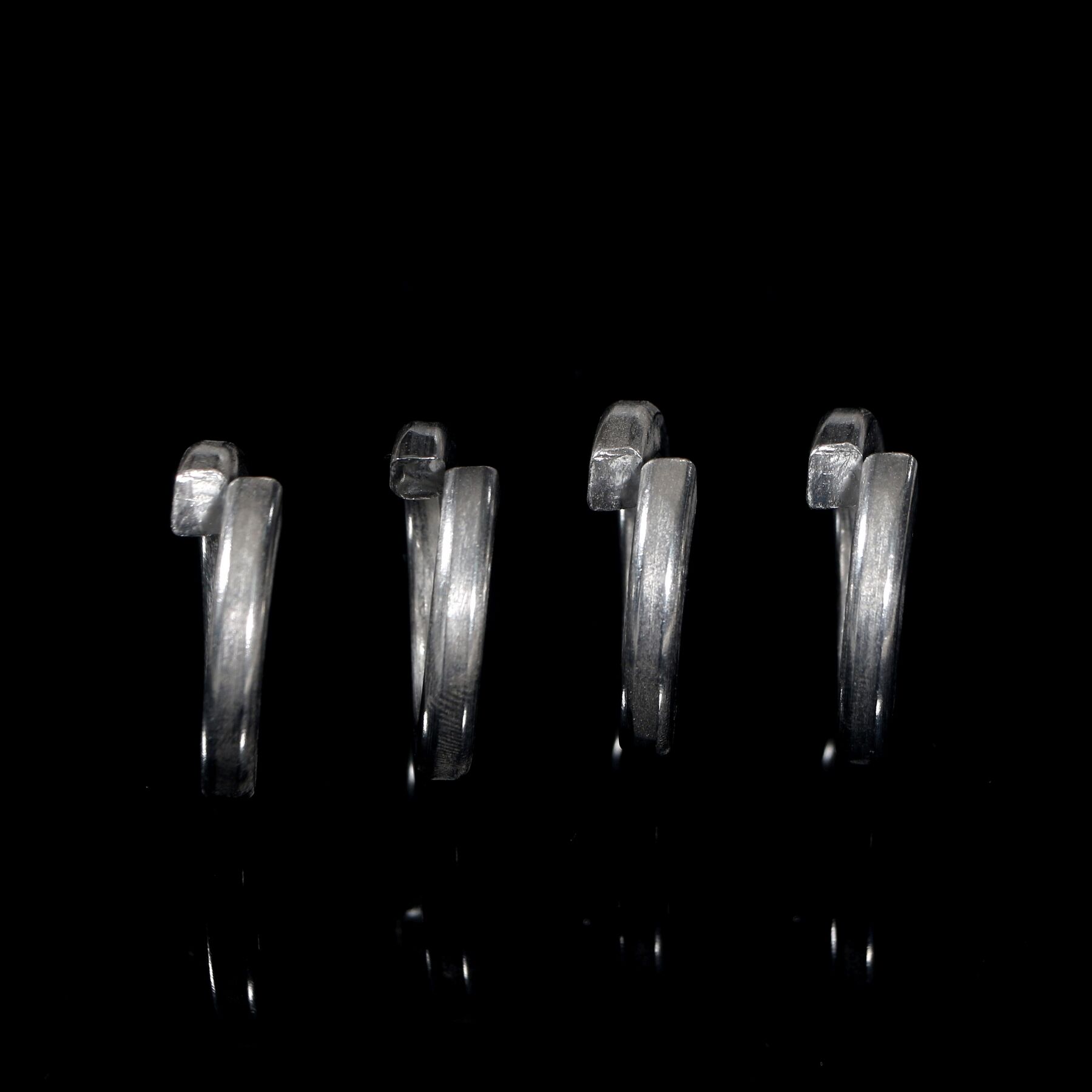

Consider metric wave washers like the glue that keeps a machine together. They are made to fill the gap between the head of the bolt and the outside application, dampening vibration and reducing the wear on the bolt. And that not only makes the machine stable, but also permits some movement when necessary, enabling the machine to adapt to varying conditions without destroying itself.

When it comes to accurate alignment of machine components, metric wave washers are the most efficient resolution. The wavy shape of the crushers makes them especially easy to match to all the areas of the machinery and to the other elements of the production cycle, to reach an external gap adjustment with a gearbox. This is crucial when dealing with sensitive instruments, in which the slightest deviation can result in catastrophe. Finally, fit the metric wave washers Products and you know everything will be perfectly lined up and running just the way it should.

2 Metric Wave Washer Tension disc pack of 10 Graphite body washers are available in a variety of sizes and are also made for a wide range of applications. Regardless of whether you need a small washer to support a light load or a larger one for heavy industrial machinery, you’ll be able to find one that meets your metric wave washer specifications. Furthermore, they can be fabricated in different materials, for example in stainless steel, carbon steel, or in plastic, according to the particular application of the machine. This flexibility makes metric wave washers a popular and dependable fastener for industrial use.

Correct installation and maintenance of GB 7244 Washers & metric wave washers are critical to their overall performance and longevity. When tightening the washer apply the same costant, uniform pressure between the bolt head and surface for an intimate connection. Inspection and replacement of worn-out washers on a regular basis can also prevent any problems and keep the machine working optimally. By practicing these simple tips, your industrial equipment will remain in top-notch condition after years of usage.

Tongxiang WANGU Standard Parts Co., Ltd., an industrial company with more than 15 years' experience in production of spring washers. We are the leader in the Chinese spring washer industry. We provide superior experiences in the procurement of raw materials and manufacturing, along with Metric wave washers and after-sales service. We have a large range of stock that we can deliver at any time. By using various management methods that we employ, we are able to reduce expenses, which is our great advantage in terms of price.

Tongxiang WANGU company is a reputable manufacturer of spring washers and flat washers.The company is primarily involved in the production of spring washers. The main standards include DIN/ANSI/Metric wave washers/JIS/UNI/ISO/BS/GB, etc. We offer a broad range of specifications, such as M1.6-M64 as well as non-standard series. We are ISO9001:2000 Certified. Our products are adored by customers in the Americas, Europe, Southeast Asia, and other regions

Our production staff of 30 are experienced and our three testing teams conduct tests every day to check the quality of the products In the meantime under the direction of ISO9001:2000 our company has reformed various systems especially in our after-sales support Beginning with the general manager we aim to be prompt and proactive respond to the issue so that buyers do not have no Metric wave washers

WANGU company has been awarded ISO9001:2000 certification. Our products are Metric wave washers superior in both quality and price. We have an experienced research team and a professional technical team.